Steering system-A basic understanding

It is not possible to run the vehicle always along straight road as road is made as per the topography. Therefore, it is necessary for driver to turn the vehicle now and then as per the road turning. It is purpose of steering wheel and steering column which transmits the rotational motion of steering to steering gears. This steering gear increases the rotational force in order to transmit greater torque to steering linkage which transmits the steering gear movement to front wheel through front axle. The steering system configuration used depends upon the type of vehicle as car or truck.

There are mainly 2 types of steering Rack and Pinion type and recirculating ball type

The Function of Steering System:

- Is to convert rotary movement of steering wheel into angular turn of front wheel.

- It helps in swinging the wheels to left and right as per requirements.

- Absorb large part of the road shocks and prevent them being transmitted to the driver.

- It provides directional stability

- It helps in wear and tear of vehicle

- It multiplies the effort of driver through linkage in order to make easy to turn the wheels.

- It should multiply the turning effort (torque) applied to steering wheel by the driver.

- When the vehicle is cornering the steering system must turn the front wheels quickly but easily and smoothly.

- The mechanism must have self righting mechanism so that when the driver releases the steering wheel after finishing the turn, the steering wheel should return to its original position.

- Proper Steering effort(when vehicle is at rest or motion elastic deformation of the tire thread due to friction between tire and ground)should be provided otherwise steering effort will be greater when car is stopped and will decrease when car speed increases. Therefore in order to maintain easier steering and better feel it should be made lighter and at a low speed and heavier at high speeds.

- The wear of tire is minimum when the relative motion between the tires and read is completely rolling type. When the vehicle is moving in a curved path the steering should be designed so that the path of points of contact of each wheel to ground are concentric circular arcs.

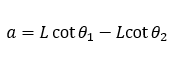

- For correct steering, the axis of rotation of all the wheels should meet at one point which is the instantaneous center of rotation of the vehicle wheels.

- To make this happen, the inner front wheel should be turned through a greater angle than outer wheel angle.

- Here smaller angle is theta 1 and larger angle is theta 2

- Davis Steering Gear

- Ackermann Steering Gear

Good post. You might also be interested in Best Electric Scooter in nepal

ReplyDeleteThis post is amazing thanks for sharing.

ReplyDeleteWelcome to IdentityPacker, your one-stop solution for cargo containers, corporate relocation, and car carriers in Noida. We offer efficient and reliable services, ensuring safe transportation and timely delivery. Trust our experienced team to handle your logistics needs with utmost care and professionalism. Contact us now for a seamless experience.

The blog is very informative and the information shared in this blog is very appreciable. We also provide Automotive engineering Consulting services. keep sharing such helpful content.

ReplyDeleteit is a Brake oil here

ReplyDeleteThat's a nice blog you made, I appreciate it. By the way, you can Find automobile news, latest cars, bikes, EV updates on my website MP Guide

ReplyDeleteGreat article! The detailed explanation of the steering system is really helpful for anyone looking to understand their car better. Maintaining your steering system goes hand-in-hand with regular tire rotation service, which not only ensures even tire wear but also improves overall vehicle handling. At Kwik Kar Auto Dallas, we provide a full range of Auto Repair and Car Repair and Maintenance services, including Engine Tune Up, Wheel Alignment, Oil Change, and DOT Inspection. If you’re looking for a reliable Auto Repair Shop offering quality Car Repair Services in Dallas and nearby areas, be sure to check out our comprehensive service options.

ReplyDelete